Mechanical simulation

LATERAL

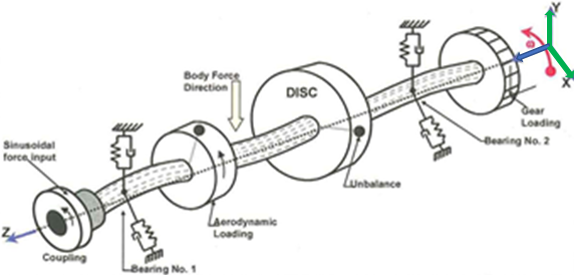

- Rotor & Support

- Flexibility of Rotor

TORSIONAL

- Rotor

- Flexibility of Rotor

AXIAL

- Rotor & Support

- Rigid Rotor

Is a process where to model the actual mechanical system in discussion by a simplified model concept or by its own physical geometry (modal analysis). In both modelling ways, the components physical properties as well as operating conditions domain have to be presented in the model, the model is usually solved by a finite element method (FEM) or equivalent.

The results of the analysis help to build a view about the system dynamics during operation (Torsional, Lateral and Axial). The simulation outcome is utilized during design stages to figure out the expectation for system mechanical performance and if any design modification needed. Also, it is utilized to issue installation recommendations (commonly known by “Alignment data”).

Other way of utilizing the simulation outcome is during troubleshooting in case of any feedback after the system get in operation. In that process the collected data from dynamic response measurement (vibration measurement), also relative alignment measurement is modelled backway (reverse engineering) in order to stand on root cause for the feedback and resolve the issue permanently.